Transducers, gauges, sensors - Information portal © 2011 - 2025 Use of material is possible by placing an active link

Thermoelectric converters (thermocouples )

Principle of operation, switching circuits and the use of thermocouples, calibration, measurement accuracy. Alloys for thermocouples manufacturing.

The principle of operation is based on the thermocouple thermoelectric effect, which consists in that in the closed circuit composed of two dissimilar conductors occurs thermo emf (voltage ), if space junctions conductors have different temperatures. If you take a closed loop consisting of dissimilar conductors ( thermoelectrodes ), then at their junctions arise thermo emf E (t) and E (to), which depend on the temperature of the junction t and t0. As discussed thermo emf are included counter, the resulting thermoelectric power acting in the circuit will be defined as E (t) - E (to).

In case of equality of temperatures of both junctions resulting thermal emf will be zero. In practice, one of the junctions of the thermocouple immersed in the thermostat (usually melting ice ) and it is determined by the relative difference in temperature and the temperature of the other junction. Junction, which is immersed in a controlled ( under study ) Wednesday, called the working end of the thermocouple junction and the second ( in the oven ) - free.

In any pair of homogeneous conductors resulting thermal emf value does not depend on the temperature distribution along the wire , and depends only on the nature of the conductors and the temperature of the junctions. If the thermoelectric circuit is open or in any location and include dissimilar conductors, it is provided that in this case all of emerged joints are at the same temperature , the resultant thermo electromotive force in the loop does not change. This phenomenon is used for measuring the Seebeck thermocouple. The resultant EMF thermocouples low: it is less than 8 mV for every 100 °C and usually does not exceed the absolute value of 70 mV.

Using thermocouples can measure temperature in the range from -270 to 2200 °C. For temperatures up to 1100 °C using thermocouples

non-noble metals , for measuring the temperature within 1100 to 1600 °C - thermocouple noble metals and alloys of platinum group. To measure even higher temperatures are heat-resistant alloys of the thermocouple on the basis of tungsten.

Currently, the most commonly used grade thermocouples use platinum, Platinum, chromel, alumel.

When measuring in a wide temperature range is necessary to take into account nonlinearity of conversion functions thermocouple. For example, the conversion of copper - constantan thermocouples for temperature range from -200 to 300 °C with an accuracy of approximately, ± 2 mV described by the formula

E = At ^ 2 + Bt + C,

where A, B and C - constants which are determined by measuring the thermal emf at three temperatures, t - temperature hot junction at °C.

The time constant ( lag ) of thermoelectric converters depends on the design of the thermocouple, the quality of the thermal contact of the thermocouple junction and the working of the object. For industrial thermocouples time constant is on the level of a few minutes. However, there are low-inertia thermocouple whose time constant is in the range of 5 - 20 seconds or even less.

Meter is connected to the loop in the free end of the thermocouple and the thermocouple in one of thermoelectrodes.

As noted above, the temperature measurement thermocouples free end should be at a constant temperature. If the length of the thermocouple is not enough, then to deflect it in the end zone of constant temperature, the wires are used , which consist of two strands made of materials ( metals) having the same properties with electrodes thermoelectric thermometer.

Thermocouple of precious metal wire lengthening made more often from the same materials as the main thermoelectrodes. Thermocouple of precious metal extension wire made of other (not expensive) materials, developing in tandem with each other in the temperature range 0 - 150 ° C, the same thermal emf as thermocouple electrodes. For example, platinum thermocouple - Platinum thermoelectrodes extension made of special copper alloy, which form a thermocouple, which is identical in the thermo emf thermocouple platinum - Platinum in the range 0 - 150 °C. Thermocouple Chromel - Alumel thermoelectrodes extension made of copper and constantan, and chromel thermocouple - Copel extension can be a major thermoelectrodes made in the form of flexible wires. If the wrong extension thermoelectrodes connect, then you might experience increased accuracy.

In laboratory conditions, the free end of the thermocouple temperature was maintained at 0 °C by placing it in a dewar filled with comminuted ice water. In industrial conditions the temperature of the free ends of the thermocouple typically differs from 0 °C and typically is ambient temperature ( room temperature ). Since thermocouple calibration is carried out at a temperature of the free ends of 0 °C and calibration tables are given relative to 0 °C, this difference may be a source of significant errors, in order to reduce the specified accuracy is usually introduced an amendment to the thermometer. When selecting the amendments recorded as the temperature of the free ends of the thermocouple and the measured temperature ( due to the fact that the function is non-linear transformation of the thermocouple ), making it difficult accurate correction of errors.

To eliminate the error is widely used automatic temperature correction introduction of the free ends of the thermocouple. To do this, thermocouple circuit and millivoltmeter included bridge, one arm of which is copper thermistor, and the remaining shoulders formed manganine thermistors. When the free ends of the thermocouple temperature of 0 °C, the bridge is in equilibrium, with a deviation of the free ends of the thermocouple temperature from 0 °C output voltage of the bridge is not zero and is added to the thermal emf of the thermocouple, while amending the readings ( correction value You can adjust the special resistor). Owing to the nonlinearity of the thermocouple conversion function full error compensation can not be obtained, but said the error is significantly reduced.

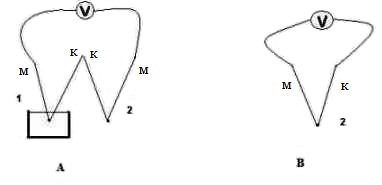

In practice, the most commonly used thermocouple following wiring diagrams (depending on the required accuracy ). For example, copper is taken thermocouple (M ) - Constantan (R )

Calibrating of thermocouple (calibration charts)

For a condition, when a free end(shut) of thermocouple is at the zero of degrees celsius. A temperature is driven to °C, E.M.F. (tension) in mV.

chromel - alumel (-270 °с to 1370 °с)

(0 °с to 1820 °с)

chromel - constantan (-260 °с to 1000 °с)

copper - constantan (-270 °с to 400 °с)

chromel - kopel (-20 to 200 °с)

Home >>Temperature, thermoelectricity >>Thermo-electric transducers - thermocouples

русский / english

• Information about various converters and sensors of physical quantities, parameters of various physical processes is presented.

• Electrophysical properties and effects in various electrical materials.

• Theory, experimental results, practical application

A) scheme, in which the free end of one is at a constant temperature ( melting ice, 0 °C). Thermo emf is generated by the temperature difference between the working and free two junctions.

B) In this scheme the free end of the temperature, it can be assumed equal to room temperature and is calculated with respect to its ( adjusted ) temperature in the working junction 2. In this case, the thermal emf in the thermocouple is formed by the junction temperature difference between the working and the room temperature.

To measure the thermo emf using voltmeters with high impedance or other type of galvanometers.

Used to determine the temperature calibration charts that are built for the condition that the free end of the thermocouple is at zero degrees Celsius. Calibration tables for chromel- alumel thermocouple, etc. are presented on the page table TXA

For measuring and researches in the laboratory terms of thermocouple it is possible to make independently. For this purpose the produced use by industry of wire from materials suitable for making ...

For making of thermocouples mostly use next alloys: kopel, alumel, chromel ...>>>

For rough measurements when sufficient accuracy of a few degrees, you can use calibration tables and their data, and readings ...

See also:

CONVERTERS, GAUGES, SENSORS

Information, news, advertising