Transducers, gauges, sensors - Information portal © 2011 - 2025 Use of material is possible by placing an active link

Thermoelectric converter

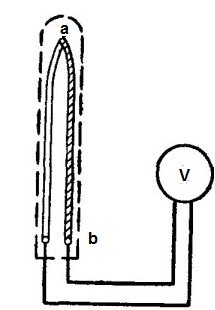

A device consisting of a thermoelectric Converter and a measuring mechanism designed to measure temperatures is called a thermoelectric pyrometer.

Thermoelectric Converter is a thermocouple connected to the measuring mechanism of the magnetoelectric system (Fig. 1).

When heated, the working end of the thermocouple occurs, the thermo-EMF, whose value depends on the temperature difference between the working and the free ends of the thermocouple. If the temperature of the free ends is unchanged, then the thermo EMF will depend on the temperature of the working end of the thermocouple. Thermo-EMF will cause a current in the circuit of the measuring mechanism, and hence the deviation of its movable part, the magnitude of which can be judged on the temperature of the working end of the thermocouple. The scale of the measuring mechanism is graduated in temperature values. The working end of the thermocouple is placed in a point, the temperature of which must be determined. Thermocouple wires must be long enough to allow the loose ends attached to the connecting wires to be in an environment with the temperature at which the pyrometer is graduated.

When measuring high temperatures, slight variations in the temperature of the free ends of the thermocouple do not cause noticeable error. When measuring low temperatures, the influence of the temperature of the free ends of the thermocouple can be very significant, and therefore sometimes to eliminate this effect, the free ends of the thermocouple are placed in a thermostat with a constant temperature.

Materials for thermocouples are: copper-Constantan (up to 300° C), copper-Copel (up to 600°C), iron-Copel (up to 800°C), chromel-Copel (up to 800°C), chromel-alumel (up to 1 300°C), platinum-platinum (up to 1 600°C).

To protect the thermocouple from mechanical damage and harmful effects of hot gases or vapors, the thermocouple is placed in a protective tube made of brass, steel, porcelain or fireclay.

The above alloys used for thermocouples have the following composition: Copel 56,5% si+43,5% Ni, chromel 90% Ni+10% Cr, alumel 1% Si+2% Al + 17% Fe+2% Mn+78% Ni.

русский / english

• Information about various converters and sensors of physical quantities, parameters of various physical processes is presented.

• Electrophysical properties and effects in various electrical materials.

• Theory, experimental results, practical application

Fig.1. Thermoelectric Converter is a thermocouple connected to the measuring mechanism of the magnetoelectric system

See also:

CONVERTERS, GAUGES, SENSORS

Information, news, advertising