Transducers, gauges, sensors - Information portal © 2011 - 2025 Use of material is possible by placing an active link

Potentiometric displacement transducers

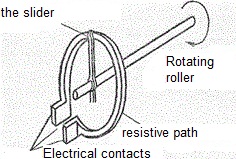

The simplest displacement converter is a resistive potentiometric divider, in which the sliding contact or the potentiometer motor moves along the resistive element (Fig.1). The engine is mechanically connected to a sensitive roller (pin), which repeats the movements of the measurement object. When a voltage is applied to the resistive element, the voltage removed from the potentiometer motor indicates the displacement value.

Linear and rotary angular displacement converters based on the principle of voltage division are widely used. Angular transmitters are used to measure angular movements from a few degrees to 7200° (i.e. up to 20 disk revolutions), while linear transmitters operate in the range from a few millimeters to several meters. These devices require electrical connections with resistive elements, which makes their design too cumbersome and limits the limit of movement during rotation. For example, a single-turn Converter is only used for measuring 350°movements.

The shape of the resistive element determines the resolution of the Converter. When this element is made of wire, the resolution depends on the number of turns of wire per unit length of the element. Other types of converters based on the principle of voltage division use a film made of plastic, metal, carbon, or a metal-ceramic mixture (known as cermets) to create a resistive element, which theoretically allows for infinite resolution.

русский / english

Home >> Manometers. Pressure gauge >> Potentiometric displacement transducers

• Information about various converters and sensors of physical quantities, parameters of various physical processes is presented.

• Electrophysical properties and effects in various electrical materials.

• Theory, experimental results, practical application

Fig. 1. Using a simple device for the potentiometric determination of the direction of rotation

See also:

CONVERTERS, GAUGES, SENSORS

Information, news, advertising