Transducers, gauges, sensors - Information portal © 2011→ Use of material is possible by placing an active link

Sensors fill level. Measurement of filling

The physical fundamentals and principles of level sensors filling. Description of the structures, characteristics, conditions of use.

Depending on the industry and environment in which it is assumed the use of level sensors filling, they have to meet certain requirements. Planning the use of gauges is necessary to know the physico-chemical properties of the filling material (viscosity, electrical conductivity, radioactivity, abrasiveness, etc.), outdoor measurement conditions - temperature, pressure, aggressive environment, etc.

There are many physical effects and properties of materials on the basis of which can be designed and manufactured sensors (measuring transducers) fill level.

Measuring with a float

As a sensitive element of the sensor the fill level of liquid is used the float. As a float, typically use a spherical body, whose density less than the density of the liquid. The transmission of information from the sensor about the level of filling can be carried out mechanically by means of various rollers, gears, wires or use electrical transmission system (linking the movement with a variable resistor, etc.). For data transmission can also be used step-by-step switches, sending a pulse, the magnetic transfer of the movement of the float, inductive displacement sensors.

Measurement errors in such devices arise predominantly due to changes in density of the filled liquid or changes in the conditions of transmission (friction, backlash, etc.).

Capacitive method of measuring the fill level. Capacitive level sensors

Capacitive measurement method, it becomes possible to measure the filling is powdery, viscous, and granular materials. Capacitive method to measure the levels of powdery food products, grains, washing powder, cement, sand, coal dust, fuel oil, fuel, water, acids and alkalis etc. Capacitive method allows continuous measurement. The error of this method is 2-3 %.

The method of capacitive sensor is based on measuring the capacitance (using the principle of capacitor). The capacitor formed by the tank wall and the probe, which is immersed in the contents of the tank. Capacity is usually measured by applying a voltage of high frequency. The capacity varies depending on the fill level. Capacity equal to the amount of containers shipped of the site and the site located in an air environment. Occurs the parallel connection of the two tanks, which total capacity is added. The accuracy depends on the design of the probe and the accuracy of the placement. The probe is made of rope, rod or tube. If necessary (if the level measurement of electrically conductive materials) is provided with an insulating coating.

русский / english

Home >> Manometers. Pressure gauge >> Sensors fill level. Measurement of filling

• Information about various converters and sensors of physical quantities, parameters of various physical processes is presented.

• Electrophysical properties and effects in various electrical materials.

• Theory, experimental results, practical application

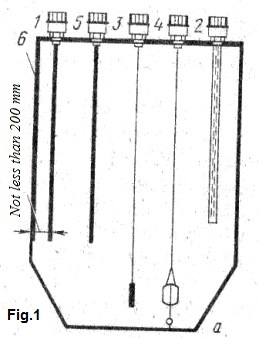

Fig.1. The location of the electrodes during a capacitive measurement method. 1 - partly or fully insulated electrode 2 and the tubular electrode, 3, 4 - electrodes in the form of wires, 5 - electrode of opposite sign, 6 metal tape

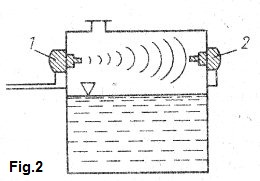

Fig. 2. Design of ultrasonic level switch. 1 - emitter 2 receiver

In Fig.1 shows the various designs of probes in a capacitive method of measuring the fill level.

If the container is made of a dielectric material, it is necessary to provide a separate opposing electrode. Sometimes in designs of gauges use a cylindrical capacitor, which open end is immersed in the measured medium.

Capacitive method of determining the filling level is universal. Probes, sensors which made in the form of a cylindrical or plate capacitor may be applied only to the fill level measurements of liquid materials.

The measurement of the filling level on the basis of electrical conductivity

The sensors for the filling level based on the conductivity method can only be used for level measurement of conductive liquid materials.

The measuring principle is based on the change in electrical resistance between two electrodes when they are immersed in filling the capacity of the material. The resistance decreases during the dive. The method and sensors used for measuring the fill level in steam boilers. The disadvantage of this method is that it can only be used for level measurement of electrically conductive fluid materials.

Hydrostatic and pneumatic methods of measuring level

Methods can be used for level measurement of all liquids. In the hydrostatic method uses the pressure of the fluid on the bottom of the vessel and its changes as the level changes. In the pneumatic method of measuring level in a tank you must forcibly feeding air or protective gas. The method and sensors used in steam-boilers, reactors, etc.

The pressure on the bottom of the tank with liquid can be measured in open containers with standard or differential pressure gauge. In closed tanks in which the liquid may be under pressure, only the differential pressure gauge. The pressure depends on the height of the liquid column and its density. If the manometer is installed on the bottom, it is necessary to make the amendment.

The pneumatic method of measuring the fill level is that the fluid level is to be measured is immersed up to a certain level. Through a special choke in the tube serving the air (or any gas). The pressure in the tube and therefore the inductor is equal to the pressure of the liquid column (and depend, respectively, from the level of the liquid) relative to the lower edge of the tube. Such measurements are called measurements by the method of bubbling gas. Tube material choose, given the physical and chemical properties liquid.

Advantages of the considered methods and sensors for measuring the fill level is their high degree of reliability.

The ultrasonic method of level measurement. Ultrasonic sensors

Ultrasonic method for the measurement of filling can be used for liquid and bulk materials. It cannot be used only if the fluid contains solid particles that can lead to large errors of measurement. This method of measurement makes it easy to automate the measurement process.

For realization of ultrasonic method of measuring the fill level you must have a source of ultrasonic waves (the emitter) and receiver. As a rule, uses frequencies from 20 kHz up to several megahertz. To receive the ultrasonic vibrations there are two ways: piezoelectric and magnetostrictive.

The as level can be, for example, the travel time of the ultrasonic beam. The speed of the beam depends on the propagation medium. This method of level measurement can serve for signaling of limit values of the filling level (see figure 2). When completing an ultrasound device sends out a signal. But for liquids easier and more precise method of ultrasonic level measurement according to the principle of the echo sounder. The ultrasound propagates in the space above the liquid is reflected from the surface (interface air-liquid) and return to the receiver is the filling level.

One of the main advantages of ultrasonic level sensor is the possibility of its application in hard to reach places.

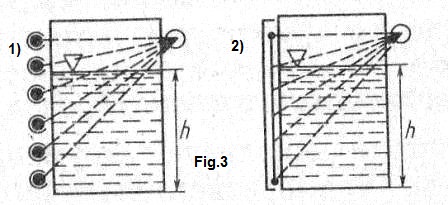

Fig. 3. Some of the options for the location of the emitters when measuring level with radioactive isotopes. 1 - some radiators, 2 - use stereaming drug

Sensors fill level on the basis of radioactive isotopes. Method of measurement

Level sensors based on radioactive isotopes, usually used where it is impossible to measure using conventional sensors. Most often the method of level measurement based on radioactive isotopes is used to measure the level of corrosive materials in tanks with high temperature, iron and steel enterprises, such materials as coal, ores, etc.

The work of the sensors based on the phenomenon of absorption of radiation by the material contained in the tank. In practice, measured, usually, thick layers of materials, so most of the sensors use γ-rays. A beam of γ-rays passes through the tank in a straight line. On the opposite wall of the tank is a receiver of radiation. The intensity of the rays reaching the receiver depends on the degree of absorption of their material. Design of sensors and systems to measure the fill level with the aid of radioactive isotopes may be different, depending on the technical conditions and requirements.

If necessary level sensor operating on the principle of the alarm device, then design it, about the same as on the basis of ultrasonic radiation (see figure 2). When you change the level and the ceiling material of the beam triggers the sensor and the measuring system.

If you need continuous measurement of the fill level, then use other designs of sensors and measurement methods. For example, when the wall of the tank is a few emitters, the rays from which are directed to the receiver (Fig.3-1). When changing the level of material overlaps a portion of the rays and the intensity of the radiation falling on the receiver is changed. Continuously variable characteristics (excluding the boundary region) of the level sensor can be received if to use instead of multiple emitters pivotal drug radiation. It is called starinavity drug Professor Berthold (Fig.3-2).

The advantages of the considered method of level measurement are: the lack of contacts, the ability to measure in particularly difficult conditions operational reliability.

Other methods and sensors for measuring the filling level

Level measurement with temperature sensors - thermocouples, RTDs. Such a measurement method is possible for the liquid non-aggressive materials. The measuring principle is based on the difference between the temperature of the material in the reservoir from ambient temperature. The design of such transducers is different, depends on the requirements and conditions of measurement.

Measurement using dynamometers. In fact, weighing the tank and the material in it. The method is suitable for measuring the fill level of bulk materials, corrosive materials. Design of measurement systems may be different and are developed in accordance with the technical requirements.

Measurement of the fill level can be carried out also using limit switches with vibrating sensing elements, measurement by displacing the body etc. There are level sensors on the basis of the interferometric method. It uses laser beams to measure distances.

See also: