• Information about various converters and sensors of physical quantities, parameters of various physical processes is presented.

• Electrophysical properties and effects in various electrical materials.

• Theory, experimental results, practical application

Transducers, gauges, sensors - Information portal © 2011 - 2025 Use of material is possible by placing an active link

Mechanical methods of measuring fill level

Measurement of the fill level of the liquid by float. Sensors

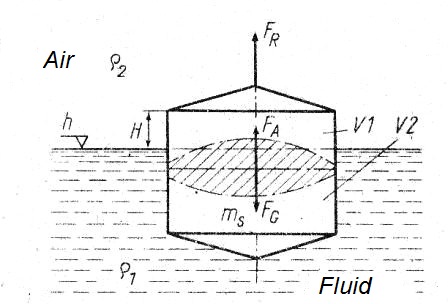

Using the float as a sensing element to measure the height of the liquid level. The physical principle of measurement is illustrated by an example of the displacement of the float on the liquid surface (Fig. 1).

русский / english

Home >> Manometers. Pressure gauge >> Float level sensors fill fluid. Measurement of filling

Fig.1. The float method of measuring the fill level of the liquid

The balance of forces on the float:

FA - FG + FR = 0;

FA = g(V1ρ1 + V2ρ2);

FG = gms,

where FA is the lifting force; FG is the gravity force of the ball; FR - response of the measuring device; ρ1 and ρ2 are densities of liquid and air, respectively.

The volume is the sum of V1 + V2 = V, i.e. the share of V1 in the medium of density ρ1 and the share of V2 in medium density ρ2.

The most important confounders are: FR, temperature T affecting the ρ1 and possibly ρ2; the pressure P2 affecting ρ2.

Changing the depth of immersion is the reason for the change of the partial volumes:

ΔV1 = -ΔV2 = -AΔH

where A is the cross-sectional area of the float.

If in the equation of equilibrium to enter as only a partial volume V1, when V2 = V - V1 we get:

g[V1(ρ1 - ρ2) + Vρ2] - gms + FR = 0.

Is usually ρ2 << ρ1, thus we obtain the following simplified equation:

gV1ρ1 - gms + FR ≈ 0.

As floats in the sensors used primarily hollow spherical or Sphero-cylindrical bodies, whose density less than the density of the liquid, so that they can float on its surface. The change in the density of the liquid or of the conditions of friction in the transmission system of the sensor leads to a distortion of the measurement result. This effect manifests itself in relation to the lifting height less than a more flat shape has a float sensor.

In the simplest case, the float sensor is attached to a rope or chain thrown over a roller or toothed wheel. In this case, the measured value is transmitted mechanically. To ensure continuous operation of the sensor to the other end of the cord or chain holding the counterweight.

With this method of liquid level measurement angle of rotation of the roller corresponds to a change in liquid level. The axis of the guide roller can be connected with the slider of the potentiometer of the sensor to effect an electrical transfer of the measured value.

A very simple mechanical method of transmission on the filling level of open tanks with a system of cables or in closed containers by entering through the seal, if the distance for data transmission is small.

However, in most cases, both in open and closed tanks level sensors used system of electrical transmission of data, especially if the measurement result is supplied to the computing device.

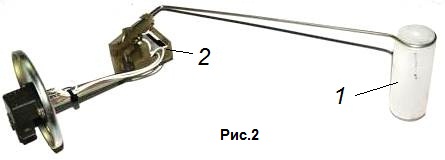

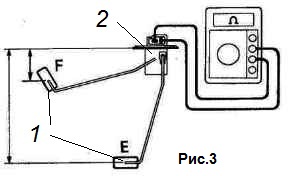

An example of a sensor of the fill level of the liquid can serve as automotive fuel level sensor (Fig. 2, 3). Here we use the so-called potentiometric method for the transmission of information about the fluid level (potentiometric level sensor). The float 1 is mechanically connected to a rheostat 2. The float moves according to the level of the liquid, mechanically moves the slider of the potentiometer (rheostat) 2. Thus, changing the output electrical resistance of the potentiometer (rheostat), which is processed and outputted by the sensor to the corresponding instrument readings of fuel level.

See also:

CONVERTERS, GAUGES, SENSORS

Information, news, advertising