Transducers, gauges, sensors - Information portal © 2011 - 2025 Use of material is possible by placing an active link

Home >> Bases of work of measuring transducers of deformation - strain gauge >> Measuring stress vibrating string. Tensometer

русский / english

• Information about various converters and sensors of physical quantities, parameters of various physical processes is presented.

• Electrophysical properties and effects in various electrical materials.

• Theory, experimental results, practical application

Measuring stress vibrating string. Tensometer

The principle of strain gauge with a vibrating string. Basic formulas, schematic design tensiometer, characteristics.

This method of measurement of mechanical stress (strain, elongation) uses the sensor steel strings stretched between two clamps fixed in the design, which studies the deformation. Changing the mechanical tension of the string changes the frequency of oscillations of ν, and Δν measurement to determine strain. One of the advantages of this method is the long service life of the sensor (transducer, strain gauge), reliability, low susceptibility to influence by external influences (humidity, radiation, etc.). These benefits provide the strength and design of strain gauge strings. In this method, a data carrier is the output frequency, which creates additional benefits in terms of resistance to interference in the form of noise, interference, transmission line effects. In addition the signal is easily converted into digital form.

The fundamental frequency of mechanical vibrations ν string stretched between two points at a distance l and subjected to the action of force F, is given by

ν = (1/2l) √F / Sρ

where S-sectional area of the string, ρ-density.

Under the influence of mechanical stress F / S string undergoes elongation Δl. Analyzing the stress strain behavior of the string an expression for the elongation (the strain) through the change of frequency:

E - Young's modulus. Knowing ν0 (initial frequency) and measuring ν1 (frequency after deformation structures), can thus determine the deformation of the structure.

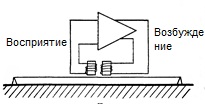

Fig.1. Strain gauge with a vibrating string

Figure 1 shows the strain gauge (scheme) of a vibrating string. Steel strings varies with the frequency of the signal ν front coil, causing periodic fluctuations in its magnetic resistance of the magnetic circuit, which generates an electrical signal at the same frequency ν. This signal is amplified and transmitted to the excitation coil that supports vibration. ν frequency can be measured with a frequency. The characteristics of this type of strain gauges can be found in the literature. For example, a strain gauge production company "Telemachus," has the following characteristics: maximum frequency of ~ 1200 Hz, the minimum frequency of about 400 Hz, range 4000mkm / m and a resolution of 1 mkm / m, the accuracy of 1 to 2% range.

Described Meter Type strain (strain gauge) is used for the control of mechanical strain and stress in construction (dams, bridges, tunnels, etc.), the weight measuring, etc.

See also:

CONVERTERS, GAUGES, SENSORS

Information, news, advertising